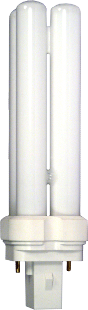

A small u-shaped or H style (biaxial shape) tube which is the most common basic

compact fluorescent bulb shape.

The DAMAR designation for this style of tube is "TT" or Twin Tube.

The GE trademarked name for this style of tube is "Biax".

The Osram trademarked name for this style of tube is "Dulux".

The Philips designation for this style of tube is "PL".

Single

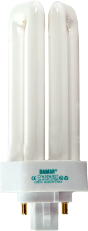

Double

"Quad"

Triple

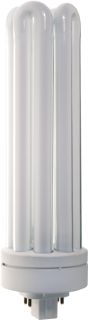

Quad

Long

DAMAR

TT

DTT & DDTT

DTT

CFM

N/A

LTT

Osram-Sylvania

DS

DD

N/A

DT

N/A

DL

Philips

PL

PL-C

PL-C (22mm)

PL-T

N/A

PL-L